"We have patents for lowering the cost of growing. Given we cannot increase the cost of our goods, we need to lower and save expenses where we can to improve the bottom line. After all, if our competitors produce for £0.80p and we produce for £0.75p we can sell at the same price and make a better bottom line margin," says Grahame Dunling, Co-founder of Worldwide Local Salads (WWLS), a UK-based vertical farming company.

After three years of thorough testing, Grahame and Matthew say to have cracked the code. Now, the firm plans to build out WWLS in a phased approach when they hit full production of 20,000 tonnes of crop annually. The site is self-sufficient and boasts planning for a vertical farm, making it one of their most ambitious and advanced projects.

"Our whole background is in salads, we should do it here and grow for quality, and texture. Unlike the so-called 'new growers' of today, they make the same mistakes over and over again. From growing many plants per m2 thinking this gives more yield, to quoting open field yield against several crops grown indoors yearly," Grahame concludes.

Matthew and Grahame Dunling

Matthew and Grahame Dunling

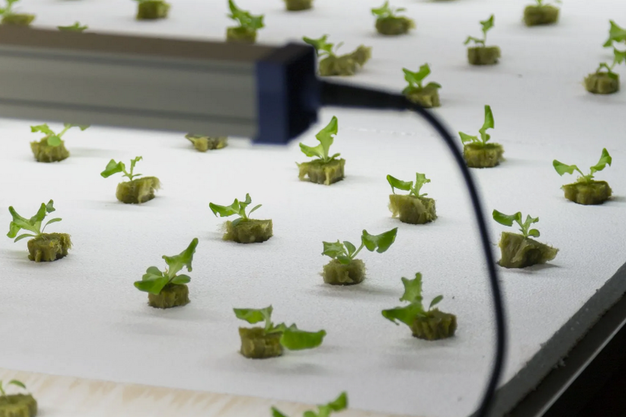

Sterile growing environment

One of the primary concerns in traditional farming is crop contamination, Grahame puts. Soil and peat can harbor harmful bacteria and pests, which can damage crops and pose health risks to consumers. WWLS's fully automated grow system ensures that plants are grown in a sterile environment, reducing the risk of contamination, and guaranteeing a healthy and safe product.

"Automation is another critical factor in ensuring consistency and quality in salad production. Our automation technology streamlines every stage of the process, from seeding to packing. By minimizing human intervention, the risk of error and contamination is significantly decreased, resulting in higher quality produce."

Renewable energy features

According to Grahame, the vertical farm site has some unique features that are rarely seen in other farms. For instance, a patent-pending wind turbine, that fits on any greenhouse fan, helps WWLS produce its energy. On top of that, they have a Wind Capture unit that allows WWLS to use a horizontal wind capture inside the warehouse (or even a Greenhouse) to produce energy. (Patent Pending) & Not to be confused with turbine usage!

"Besides our LED lighting system that helps us save 50% in capital, and 35% in OpEx, we have a Syphon design for our mobile gutter system which we use to control 100% of the plant irrigation to ensure all plants receive an equal amount of feed and water," Grahame affirms. Given the farm is computer-controlled, they can run the farm from anywhere in the country, and world, "making the risk element a lower point of concern."

A family affair

The Dunling family, with over 200 years of family growing experience, has a rich history of producing high-quality crops around the world. Their secret? A combination of natural and controlled environments that prioritize taste, texture, and longevity, as Grahame likes to think.

"Sustainability is at the core of our operations," Grahame explains. The facility comprises of multiple on-site generation capabilities to minimize the carbon footprint and reliance on external energy sources. As well as, hot water storage tanks, to further reduce the farm's environmental impact. This means that excess heat generated during the day is stored and used during the night, e.g.

WWLS has partnered with Viemose DGS, a supplier of Moving Gutter Systems, with over 35 years of experience in the industry, to ensure access to technology and expertise, allowing WWLS to provide consumers with high-quality produce.

For more information:

For more information:

Worldwide Local Salads

Grahame Dunling, COO

grahame@localsalads.com

www.localsalads.com