Leafy greens like arugula, spinach, and baby leaf aren't just tasty - they're nutritional powerhouses packed with vitamins, minerals, antioxidants, and fibre. As consumers increasingly seek healthy yet convenient plant-based options, the demand for packaged, pre-washed mixed salads and ready-to-eat greens is booming worldwide.

But here's the challenge: leafy greens are fragile. During processing, they're prone to mechanical damage and microbial contamination that can seriously affect quality, safety, and shelf life. So, how can producers keep these delicate vegetables fresh and safe from field to fork? This is where Sormac comes in.

© Sormac

© Sormac

Decades of expertise in leafy greens processing

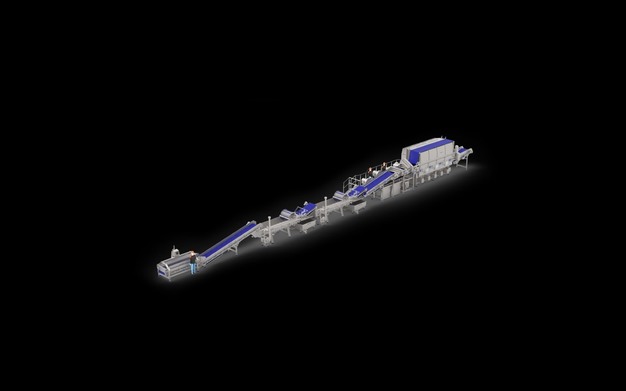

Since the 1990s, Sormac has been a known name in vegetable processing technology. Their precision-engineered equipment is specially designed to handle fragile leafy greens on an industrial scale, which helps processors to tackle the unique challenges of mixing, washing, and drying these sensitive products, including 3rd party equipment integration.

© SormacLeafy greens washing and drying line

© SormacLeafy greens washing and drying line

The Microbiological Lab: A unique industry resource

In 2015, Sormac launched an in-house Microbiological Lab. This facility supports both customers and Sormac's own R&D and engineering teams in areas like hygiene, product integrity, and processing efficiency.

The lab provides vegetable processors with valuable insights into their own production lines. By carefully analyzing samples from critical points in the process, Sormac helps identify exactly where and how damage occurs—and offers practical advice on how to prevent it.

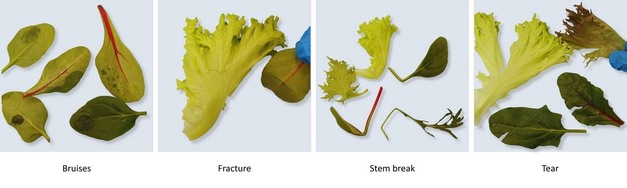

"We take samples from multiple points along the line and analyze them for signs of mechanical damage like tearing, bruising, and stem breakage," explains Marianne Knorr, Quality Assurance Officer and Head of the Sormac Lab. "We then advise processors on how they can optimize their own processes."

Why even minor damage matter

It might surprise you how small abrasions or bruises can have a big impact. Damage to the leaf's protective surface can disrupt the natural microbial ecosystem, making greens more vulnerable to spoilage and harmful pathogens, especially when temperature and humidity fluctuate during processing or storage.

© SormacAvoiding damage to leafy greens

© SormacAvoiding damage to leafy greens

Gentle handling for better results

To protect leafy greens, Sormac's machines focus on gentle, intelligent handling at every step. Their Pulstar washers use low-turbulence water flow and customizable wash cycles to clean thoroughly without stressing the leaves. Sormac's air-drying tunnels, LDT, are also specifically designed to gently dry delicate leafy vegetables while preserving product quality. Inside the tunnel, a regulated upward airflow causes the product to float, achieving surface moisture levels below 1%.

A partner in quality from field to fork

"Our mission is to enable processors to deliver the best possible product to the consumer," says Marianne. "That means more than just efficiency - it means protecting the nutritional value, food safety, and appearance of every single leaf."

Today, Sormac supports salad producers, fresh-cut processors, and foodservice suppliers worldwide with equipment, industry knowledge, and advice. Leveraging the insights and resources of their Microbiological Lab, Sormac's specialists also offer on-site audits and tailored support, helping customers optimize processes and improve product quality across their entire production lines.

For more information:

Sormac

Tel: +31 (0)77 351 84 44

Email: [email protected]

www.sormac.com