Vertical farming, and the complete precision that Total Controlled Environment Agriculture (TCEA) offers, provides growers with a vast number of variables that can be modified to alter crop growth, or improve operational efficiencies. These variables, such as light intensity or temperature, can be linked to crop outcomes including yield or morphology. Intelligent Growth Solutions (IGS) can then take data from this process, resulting in large, invaluable datasets. This helps IGS to achieve higher quality harvests, and improves overall site efficiency.

IGS leverages data generated by their Growth Towers to improve the intelligence of their system, ultimately making it easier for customers to get the information they need to successfully grow crops. By enriching standard data streams with machine intelligence, IGS can generate observable insights, refine recipes to suit different crops and circumstances, and perform environmental health checks. Intelligent use of data is crucial here. Not only does it ensure a high performing system, but it will also be an increasingly critical part of how the agritech industry operates in the coming years.

Using visual imagery to showcase data

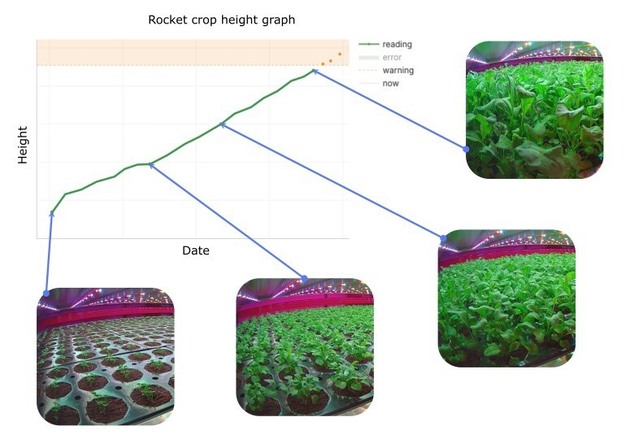

Growers can monitor the progress of their crops within the Growth Trays via cameras mounted on either side of the lift. These generate images – removing the need for crops to be taken out of IGS' system for quality checks, and also containing a wealth of data that can be extracted to provide further insights.

By leveraging the known dimensions of the Growth Tray and the surrounding tower structure, IGS can accurately calibrate each camera to extract 3D metrics of the crop, such as height and uniformity. Initially, this calibration process was conducted manually. However, the company has since implemented a machine learning model capable of automatically performing feature recognition and extraction, thereby enhancing the frequency and standardization of the calibrations. This advancement results in quicker and more consistent analyses, offering customers several benefits: more precise crop height tracking, easier detection of subtle differences between growth cycles, a foundation for developing new monitoring tools, and the ability to identify any changes in calibration.

This automation removes the need for manual workflows, allowing IGS to scale up these solutions to more towers, sites, and customers.

© Intelligent Growth Solutions (IGS)

© Intelligent Growth Solutions (IGS)

What insights can be taken from this

Automated image analysis allows IGS to track several variables and detect specific events, such as when a crop is reaching a height where it is at risk of damage. This data can also be used to reveal patterns during recipe development or trials. If a crop isn't growing at the rate that is expected, for example, it can be a sign that factors such as lighting, nutrient mix, or watering frequency need adjusting. This kind of feedback is key in helping the IGS team of crop scientists to be agile, rapidly remedying any issues that might arise.

IGS are also investigating how to apply predictive analysis based on growth curves, and the process of site-wide forecast models for harvest delivery. This work is still in the early stages, but they are excited about its potential for integration into IGS' software suite.

The crop segmentation tool

Another good example of how to translate imagery into tangible data would be IGS' custom crop segmentation tool. This takes standard images from tower cameras and automatically segments the plants from the background in each image. The result allows IGS to focus on crop pixels, and monitor factors like plant health, coverage and development. This becomes much simpler as IGS can effectively isolate the plants from any other noise, giving growers access to tangible datapoints on what matters most – the plants.

Supporting data-driven crop recipe development and refinement

Data is important to both scientists and operators, shaping the way that IGS' customers explore and execute growth recipes. IGS record datapoints in every Growth Job, including lighting schedules, irrigation, environmental conditions, and what crop outcomes were achieved under these conditions. The combination of this data is a centralized logbook, storing a huge amount of information which IGS can share with its customers, and also use to implement improvements to the product. The tools can compare datapoints across different growth cycles, seeing the impact certain changes can have over a set period.

© Intelligent Growth Solutions (IGS)

© Intelligent Growth Solutions (IGS)

Using data for environmental health checks

To maintain a controlled environment, the IGS software continuously monitors and integrates data from a network of sensors distributed across the towers, providing real-time feedback on crucial variables such as tower temperature, humidity levels, water pH, water electrical conductivity (EC), and tower CO2 concentration.

Complex control loops keep environmental conditions within the defined setpoint ranges, and IGS can monitor the interaction between these variables to paint a more detailed picture of the current environment in the towers. IGS teams have access to augmented diagnostic data, enabling them to gain a deeper understanding of the technology and its impact on crops. This continuous feedback loop helps to maintain each Growth Tower's microclimate at an optimal level, while supporting healthy, predictable plant growth.

The role that data can play in the future of growing

As the agritech industry evolves further, growers see data playing an even greater role in influencing how the workforce uses technology in day-to-day operations. The platform is positioned to lead that shift. It works to embed various degrees of automation, not as a way of replacing people, but of freeing them from repetitive, manual inspections so that they can focus on creative, higher-value tasks.

The data that IGS collects can be implemented in advanced analytics, working to feed machine learning or AI models which can then deliver even more powerful insights. By ensuring that they have the right datapoints and are concentrating on the right metrics, IGS can put in place a data-rich approach which makes for a wholly more intelligent way of working.

For more information:

Intelligent Growth Solutions (IGS)

Andrew Lloyd, CEO

Tel.: +44 (0)131 202 1050

www.intelligentgrowthsolutions.com