"We've been doing hydroponics and vertical farming for about five years," says Ahmed Fawzy, CEO of Taza Farms. "We originally grew for human food, supplying London's top restaurants and hotels. We wanted to do something with more impact, so we took our hydroponics experience into animal feed."

That decision led to Taza's first full-scale pilot at Hunsingo Dairy in Groningen, the Netherlands. "This pilot became our first paying customer," Fawzy says. "The feedback has been better than we hoped. The cows went for the fodder straight away, farmers noticed it's easier to digest, and our system delivered a fresh, consistent supply every single day." © Taza Farms

© Taza Farms

Ahmed Fawzy (left) and Nasir Sharif (right), founders of Taza Farms

How the system works

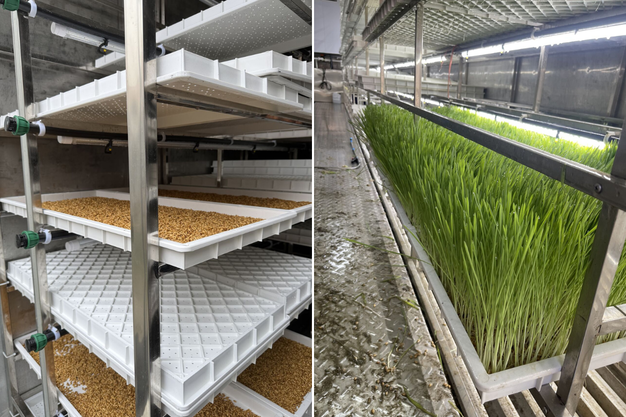

"We use a vertical hydroponic container system," explains Sylvana Vanderkaa, Chief Marketing Officer. "We sow seeds in trays, add water, and in just seven days we harvest a fresh, wet fodder mat."

"Every day you sow one part and harvest one part, so you have a continuous daily output," she says. "It's just seeds and water in trays, no separate substrate. The root mat forms flat across the tray." © Taza Farms

© Taza Farms

Results from the Netherlands pilot

The company reports that during the two-month Hunsingo pilot, the system ran at 98.5 percent uptime. The container produced around 1,000 kilograms of fresh barley fodder daily, enough to feed 100 cows. "The cows eat the feed quickly because it's so fresh," Vanderkaa says. "It's easier to digest, so they expend less energy eating. The farmers reported higher milk yield and higher butterfat when the wet fodder was included."

Reported outcomes included a 12 percent increase in milk yield to 32.5 liters per cow per day, higher butterfat content at 4.2 percent, protein content at 3.4 percent, and an improved income over feed cost of $8.50 per cow per day. Feed efficiency was measured at 1.4 kilograms of fodder per liter of milk.

A choice for farmers

"There are two options," Vanderkaa says. "Either we do the full process and the farmer just buys the feed, or they buy the container and run it themselves."

"Where we differ is offering farming as a service," Fawzy says. He stresses the importance of ongoing support. "We can run the container end to end and deliver fresh feed daily, so the farmer only pays for feed instead of managing the unit. A lot of attempts fail when a small part breaks and the farmer can't maintain it. Our service model avoids abandoned systems." © Taza Farms

© Taza Farms

Looking ahead

Reflecting on the pilot, Fawzy says, "Watching the cows tuck into our hydroponic fodder has been one of the most rewarding moments of this journey. It's taken late nights and a lot of muddy boots to get here, but we're excited for what's next. This isn't just an idea anymore. It works."

The company now aims to raise £1M in seed funding to scale its work into the Middle East. "This region imports hundreds of millions worth of feed every year, with huge pressure on land and water. We believe Taza's hydroponic fodder is part of the solution."

For more information:

Taza Farms

Ahmed Fawzy, CEO and Co-Founder

[email protected]

www.tazafarms.com