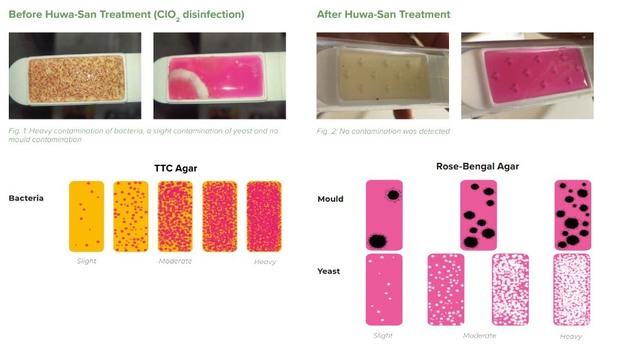

Recently, Roam Technology conducted an assessment aimed to evaluate the hygiene challenges in a post-harvest washing system and the effectiveness of Huwa-San TR-50. Persistent biofilm formation, poor water quality, and the presence of pathogenic microorganisms were identified as key issues affecting product safety and shelf life. The performance of Huwa-San TR-50 was examined to determine its efficiency in reducing microbial load and maintaining a clean water system.

The challenge

Upon arrival at the processing facility, the vegetables are washed to remove dirt. The water system showed significant biofilm formation, which can harbour and protect various microorganisms. The washing water was of low quality, with a high microbiological load and low oxygen levels. Pathogens such as Escherichia coli and Salmonella were detected in the water, and common post-harvest pathogens in leafy vegetables—Erwinia, Sclerotinia, and Botrytis cinerea—were found on the fresh produce. These factors contributed to a reduced shelf life of the crops.

The chlorine dioxide (ClO₂) tablets, previously used for water disinfection, required a final rinse with potable water to remove residual chlorine before packaging, adding extra washing steps and thereby increasing operational costs. Despite these efforts, the chlorine-based treatment proved ineffective in reducing the microbiological load of the water and in preventing biofilm formation within the system.

© Roam Technology

© Roam Technology

The solution

Making the switch from Chlorine Tablets (ClO₂) to Huwa-San TR-50: The chlorine dioxide tablets were replaced with Huwa-San TR-50, an advanced broad-spectrum disinfectant based on silver-stabilised hydrogen peroxide.

Disinfecting water tanks: The water tanks were sprayed with a 6% Huwa-San TR-50 solution and left to dry completely before refilling. No rinsing with fresh water was required, as Huwa-San leaves no toxic residues and breaks down into water and oxygen.

Disinfecting the water system: A Clean-In-Place (CIP) disinfection cycle was performed using a 1% Huwa-San TR-50 solution for 30 minutes to effectively remove biofilm deposits and disinfect the entire water distribution system.

Continuous water dosing treatment: A dosing pump continuously added 20 ppm of Huwa-San TR-50 into the main water tank to maintain system hygiene and prevent biofilm reformation. A second dosing pump added an additional 60 ppm directly into the pipeline before the water entered the post-harvest washing unit, ensuring a minimum concentration of 70 ppm in the washing water used for fresh produce.

Implementing Huwa-San TR-50 delivered high-quality, oxygen-rich washing water with no chemical residues, odor, or aftertaste. Because the product naturally decomposes into water and oxygen, no final rinse was required, resulting in lower operational costs. Additionally, the water system remained free from biofilm, ensuring consistent hygiene and system efficiency. As a result, fresh produce stayed firmer and fresher for longer, thanks to the elimination of pathogens, thereby extending shelf life and increasing market value.

For more information: Roam Technology NV

Roam Technology NV

Geleenlaan 24

3600 Genk

Tel.: +32 89 44 00 42

Email: [email protected]

www.roamtechnology.com