In Chile, AgroUrbana is taking vertical farming to new heights – literally. Using AI and renewable energy to grow crops and IFCO reusable crates to help streamline distribution, this model could change how the world feeds its cities. Co-founder Pablo Bunster explains why.

You have quite the interesting background. What drew you personally to vertical farming?

My business partner Cristián Sjögrens and I both come from Chile's renewable energy sector. During the energy crisis, we set out to prove that renewables – solar and wind – could be competitive without subsidies. Within a few years, renewables went from being impossible to covering up to 50% of the world's electricity needs.

We both then asked ourselves what's the next big challenge. That's when we came across vertical farming, which ties in nicely with our background in renewables. We knew we could make it work in Chile.

Why Chile? What makes it the ideal place for vertical farming and agtech start-ups?

The global population is growing and concentrating around urban areas. Chile is just a reflection of how extreme it's becoming. The country is highly urbanized, with major cities and a growing population who want fresh, reliable produce at a competitive price. But climate change and logistics make that hard. We have limited resources, and we have increasing demand. Basically, we need to do more with less, and vertical farming is one way to achieve that.

What's more, a fundamental piece of the puzzle in vertical farming is energy. In Chile, we now have an abundance of renewable, competitive energy. If you pair vertical farming technology with low-cost renewables, the model is viable and sustainable.

High-tech vertical farming isn't just a niche, nice-to-have option for high-end markets. If vertical farming can work in a developing country at the end of South America, it can work anywhere.

In the meantime, you've built Latin America's first large-scale vertical farm.

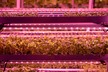

We built the prototype in 2018 and scaled rapidly to full commercial operations in 2021. We started with leafy greens – mainly lettuce and basil – because they're the everyday staples with a huge market. The reason being, if you can compete on lettuce, you can compete on anything.

By 2021, we had already multiplied our production capacity by five, thanks to an amazing team of talented people, including plant specialists, growers, and computer scientists. Today, it's ten times higher. Within the next year, we expect to increase our production capacity by almost 25 times that of 2020.

© IFCO

© IFCO

How exactly does vertical farming technology work?

Instead of battling climate variability, we create our own climate. It hasn't been easy, but we built our own climate. We're a data-driven company that gives our plants 365 days of spring.

By controlling light, carbon dioxide, temperature, and nutrition, we grow plants of consistent high quality all year round. Our products are fresh, tasty, and ready to eat – with no pesticides. We are local at scale.

And what makes vertical farming technology sustainable?

We produce over 100 times more crops per square meter compared to open-field farms, thanks to vertical stacking and faster growing cycles. In our facilities, we get 12 growing cycles per year instead of the usual three you might get on land in a Mediterranean climate.

We use only 5% of the water that is usually required in open-field farming. We achieve this by recycling humidity and transpiration from the plants. Crucially, we will have transitioned to 100% renewable energy in the near future.

We don't apply any kind of agrochemicals. In fact, our products are so clean that we don't need to wash them – and we tell our customers not to as well. Our leafy greens are ready to eat!

With our products, you get sustainability but also health, flavor, freshness, convenience, traceability, and no waste.

There's a lot of interest in your products already. What do your clients value most about your vertical farming model?

Today, our clients include the main supermarket chains in Chile and South America – which we're very proud of – high-end restaurants, large-scale food-service companies, and a growing direct-to-consumer subscription model.

What we're doing is bringing stability to the market, which is traditionally hard in agriculture because of its inherent volatility. Our clients value consistent delivery and product quality, and we have predictability over our cash flows. We're therefore de-risking operations for both sides.

This is something we learned in the energy sector. That works on long-term contracts, and we want to bring the same kind of reliability to the food sector.

How does your partnership with IFCO fit into your model?

IFCO reusable packaging is an integral part of the fresh grocery supply chain in Chile. We transport our products in IFCO reusable crates to all our supermarket clients.

Because of its scale, the IFCO SmartCycle is efficient and competitive, as well as sustainable. We've been working with IFCO since the early days. Even though we were a small start-up at first, IFCO worked closely with us to bring us on board. With IFCO, we get circularity and sustainability at no cost to efficiency.

That's because IFCO takes care of the logistics seamlessly for us, and we enjoy a reliable service and the environmental benefits of reusable packaging. We're very happy with our relationship. It works!

© IFCO

© IFCO

Food safety is also at the core of the IFCO SmartCycle. What food-safety benefits do IFCO reusable crates bring to your daily operations?

It's crucial that the packaging we use truly delivers on its promises! IFCO reusable crates come sanitized, so we don't have to do the work. This is a great upside of working with IFCO.

For our clients, this is a huge advantage. They have security, we de-risk contamination, and provide full traceability.

How do we do this? Well, you can choose to use a sophisticated system, or you can achieve food quality, food safety, and traceability through simplification. We chose to simplify the process. And we have a very rigorous food-safety team.

Everything, from seeding to packing, happens under one roof – our roof. That gives us control and makes traceability simple and robust.

© IFCOAgroUrbana founders Pablo Bunster and Cristián Sjögrens

© IFCOAgroUrbana founders Pablo Bunster and Cristián Sjögrens

What has been the most surprising part of working in vertical agriculture?

It's been full of surprises! There's a lot of theory about what we're doing, but it's also trial and error. There's a huge learning curve.

We had to build our own AI-based operating system to manage everything. The solution we're scaling today – everything from hardware to software and sensors – is built in-house.

Now that brings us high-quality data. We can keep going back to that data. We make sure that we get as many things wrong as possible as fast as possible – and then we fix them.

Where do you see vertical farming technology heading?

Our mission remains the same: to provide fresh, healthy, sustainable food for everyone. It's hard to imagine how vertical farms will work in five- or ten-years' time.

So much is happening, and vertical farming technology is maturing. Right now, we're focusing on making this company a viable and very profitable operation.

Source: IFCO

For more information:

AgroUrbana

agrourbana.ag/