Monterey Mushrooms uses byproducts of the cottonseed oil industry and of the wheat harvest to grow its mushrooms. Its Polyethylene Terephthalate (rPET) tills are made from 100% post-consumer materials. Used bedding from Santa Anita's racehorse stables helps fuel compost. The Watsonville, California-based company's commitment to a sustainable, circular economy can be found throughout operations on its seven North American farms, which grow 20 million pounds of organic white and brown mushrooms each year along with its conventional mushroom lines.

One piece, however, stuck out of the circle like a nail in a tire—the farm's spent mushroom compost. The Morgan Hill, California farm produced more of the nutrient-rich byproduct than it could convey to local farmers for the soil in their fields. At times, the company would have to pay to have it hauled off, says Chris Thomsen, operations manager, Monterey Mushrooms, "which is a really sad thing."

Thomsen and his team realized that organic certification for the spent mushroom compost would help close the loop and enable the many local organic farms to use it in their fields. Thomsen and his quality assurance supervisor began the certification process through the California Department of Food and Agriculture (CDFA).

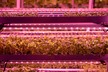

Things move quickly on a mushroom farm. Fast-growing fungi mean "every other day, we produce new crops," explains Monterey Mushrooms marketing manager Lindsey Occhipinti.

Read more at Organic Produce Network