Grow Dynamics was commissioned to deliver a vertical farm research facility in Suffolk dedicated to strawberry and vanilla cultivation. The project required highly precise environmental control, including reliable low-temperature performance, to support crop optimisation and variety testing. Working in collaboration with Panasonic's Technical Sales Account Manager, Rob Towell, Grow Dynamics selected Panasonic's advanced low-temperature heat pump technology as part of the overall system design.

The Grow Dynamics scope included full system design and integration across climate control, irrigation and fertigation, grow lighting, automation and centralised monitoring. Alfonso Cenname, Head of Engineering, and Vlad Petryk, Director at Grow Dynamics, led the design, specification and installation of four Panasonic 14kW adaptive ducted twin split systems. This configuration delivers precise and consistent climate conditions, enabling accurate control of the crop environment and supporting the testing of new crop varieties.

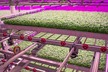

The fully enclosed facility comprises four independent grow rooms constructed from insulated, food-grade panels, each designed to house approximately 4,000 plants. Achieving consistent, high-quality yields required meticulous control of temperature, humidity, lighting and irrigation within each room. Three rooms were dedicated to strawberry cultivation and one to vanilla, each with distinct environmental requirements. Strawberries thrive at 10-12°C at night and 22°C during the day with 60–70% humidity, while vanilla requires warmer, more humid conditions to replicate a tropical climate.

© Panasonic

© Panasonic

Rob Towell recommended the Panasonic PACi NX low-temperature units for their energy efficiency, performance and reliability. Each grow room was equipped with two adaptive ducted indoor units paired with a dedicated outdoor condenser. Grow Dynamics integrated its proprietary VertiOne control and fertigation platform to synchronise climate, irrigation and lighting systems within a fully closed-loop growing environment. The advanced irrigation system delivers fertilised water through a closed-loop recycling process, achieving a 90-95% reduction in water usage compared to traditional growing methods. Lighting systems were configured to replicate natural daylight cycles and synchronise with temperature changes to reflect day and night states.

© Panasonic

© Panasonic

This project reflects Grow Dynamics' approach to controlled-environment agriculture: delivering fully integrated, crop-specific systems where climate, irrigation, lighting and digital control operate as a single optimised platform.

Alfonso Cenname commented, "During our evaluation of available options, Panasonic's units stood out as the only solution on the market capable of reliably meeting the precise temperature requirements within the defined project scope."

© Panasonic

© Panasonic

Since installation at the end of June 2025, the Grow Dynamics designed controlled environment has consistently delivered high-quality strawberry production year-round. Panasonic's units have enabled stable, repeatable climate conditions that support consistent crop performance, and Grow Dynamics plans to continue using Panasonic solutions on future projects due to their sustainability and reliability.

Source: Panasonic