Basil cultivation in controlled environments has become one of the most technically and economically challenging crops in indoor agriculture. Its agronomic sensitivity, combined with market-driven cost pressure, has caused many vertical farming projects to fail.

Against this backdrop, Galicia-based Néboda Farms has been working since 2019 on the development of a hydroponic production model that applies industrialization, automation, and continuous improvement principles with a clear objective, producing basil year-round with consistent quality, guaranteed supply, and prices aligned with conventional agriculture.

"Our goal was never to create a niche or premium product," explain founders Samuel López and Iván García. "From the start, we believed the product had to target a mass market, and to do that, it had to compete on price with traditional farming."

© Néboda Farms

© Néboda Farms

A name rooted locally with global ambition

The origin of Néboda Farms reflects both its geographic roots and its long-term vision. "We are from Galicia and based in Vigo, and néboda or néveda is a plant that was traditionally used in Galicia for cooking chestnuts and later spread worldwide," the founders explain. "For us, it represents a dual meaning, a strong connection to our land and, at the same time, the intention to expand globally."

The company was established in 2019, when the team began an in-depth study of hydroponics and the specific requirements of basil cultivation. Operational activity started in 2020 with the acquisition of a commercial vertical farming system installed in a maritime container.

"That first phase allowed us to validate crop behavior, but it also revealed the economic limitations of conventional vertical farming," they note. "The basil looked very good, but production metrics were not sufficient, as annual yield per square meter did not support a viable business."

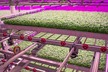

Based on these findings, the company decided to completely redesign its system architecture toward the current model, inspired by automated logistics warehouses. In this setup, cultivation trays are arranged horizontally and stacked vertically, supported by an automated operational flow.

The system combines standard machinery to reduce capital expenditure and technological risk, with proprietary equipment developed in-house. The focus is on operational optimization and reducing operating expenses, particularly labor, energy efficiency, process integration, and equipment robustness.

© Néboda Farms

© Néboda Farms

Operating costs as the critical factor

Néboda Farms highlights that one of the most common mistakes in vertical farming has been prioritizing technology without resolving the cost structure. "Capital expenditure is amortized over a long time frame, but operating expenses directly impact the cost of each product. If OPEX is not controlled, the model is not sustainable," the founders state.

For this reason, the company applies lean manufacturing methodologies borrowed from the automotive industry, with close monitoring of production metrics and small-scale validation before any growth phase. "This way of working allows us to avoid one of the major problems in the sector, scaling too quickly with systems that were not yet optimized."

Scaling up in 2027

Currently, Néboda Farms operates a pre-industrial facility with 100 square meters of cultivation area dedicated exclusively to basil, achieving up to 26 production cycles per year. "On the commercial side, we are already working with large distributors, but we have chosen to be cautious before taking the next growth step, the construction of our first industrial facility with 1,800 square meters of cultivation area."

The company plans to follow the same operational strategy in the new facility and is also evaluating the addition of new high-value segments such as baby leaf mixes. However, the primary objective of the project is to reach a true break-even point.

Construction is expected to begin in the fourth quarter of 2026, with completion planned during 2027. "With this step, we aim to become one of the first companies in the world to demonstrate, through technical and economic auditing, that vertical farming can be profitable."

"This milestone could mark a turning point for the sector. There is a clear need for efficient and profitable agriculture, and once a vertical farming company proves real profitability, there is no doubt that investment will return to the sector."

© Néboda FarmsFor more information:

© Néboda FarmsFor more information:

Néboda Farms

[email protected]

www.nebodafarms.com